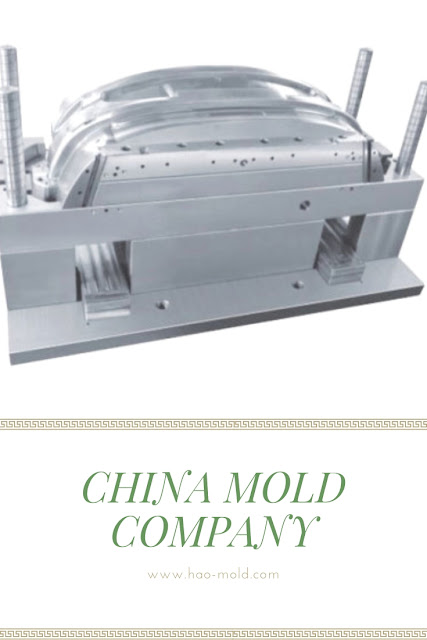

What Are the Advantages of Choosing Plastic Injection Molding?

What Are the Advantages of Choosing Plastic Injection Molding? You need to know about plastic injection molding. Plastic injection molding is one of the very effective techniques for making complex plastic parts at large volume. It is not merely exceptionally effective, but additionally really variable used with the choice to create improvements to the base product throughout the creation process. Let us take a look at several of the very desirable qualities of using plastic injection molding:

High precision

Plastic injection molding is a manufacturing strategy that is highly appropriate provided a precise mold is used. Typically, the reliability level is likely to be in the location of approximately 0.006 inches.

Quickly and successful

The quickly and successful character of this kind of production makes it the most used selection for producing a large volume of plastic items. But injection mold china, the particular time to generate each bit can vary with the complexity of the actual mold. A typical time to generate each object is in the area of 15 to 25 seconds.

Maintains labor charges to the very least

The computerized character of plastic injection molding helps to cut labor expenses because this sort of machinery just needs a minor workforce to help keep going. Once the actual mold is made, the equipment will keep running properly with proper guidance in place.

Reduce spend

The capacity to minimize spend and gain the surroundings is particular to be an fascinating quality for many. This kind of equipment is not merely very efficient, but can be appreciated for the tiny amount of spend produced during the time of production. It only must utilize the collection volume required to generate each shaped piece. Also, when there is any waste, this will simply be recycled elsewhere on a different project.

Easy to alter production

Plastic injection molding is made to provide great mobility with the possibility to create changes through the manufacturing process. Many of things that can actually be transformed contain the sort and color of product used.

High-strength parts

The pieces produced using this production technique can very quickly vary in strength. A simple way to improve on the all-round power of a part is to include a unique form of filler to the base plastic material. It has the advantage of reducing the amount of liquid plastic which benefits in good strength and longevity of the completed item. The ability to control the plastic strength makes plastic injection molding a great option for any business that requires the tremendous solid products.

High precision

Plastic injection molding is a manufacturing strategy that is highly appropriate provided a precise mold is used. Typically, the reliability level is likely to be in the location of approximately 0.006 inches.

Quickly and successful

The quickly and successful character of this kind of production makes it the most used selection for producing a large volume of plastic items. But injection mold china, the particular time to generate each bit can vary with the complexity of the actual mold. A typical time to generate each object is in the area of 15 to 25 seconds.

Maintains labor charges to the very least

The computerized character of plastic injection molding helps to cut labor expenses because this sort of machinery just needs a minor workforce to help keep going. Once the actual mold is made, the equipment will keep running properly with proper guidance in place.

Reduce spend

The capacity to minimize spend and gain the surroundings is particular to be an fascinating quality for many. This kind of equipment is not merely very efficient, but can be appreciated for the tiny amount of spend produced during the time of production. It only must utilize the collection volume required to generate each shaped piece. Also, when there is any waste, this will simply be recycled elsewhere on a different project.

Easy to alter production

Plastic injection molding is made to provide great mobility with the possibility to create changes through the manufacturing process. Many of things that can actually be transformed contain the sort and color of product used.

High-strength parts

The pieces produced using this production technique can very quickly vary in strength. A simple way to improve on the all-round power of a part is to include a unique form of filler to the base plastic material. It has the advantage of reducing the amount of liquid plastic which benefits in good strength and longevity of the completed item. The ability to control the plastic strength makes plastic injection molding a great option for any business that requires the tremendous solid products.

Comments

Post a Comment